Filamentous Bulking Control with Hydrogen Peroxide

Basis of Control with Hydrogen Peroxide

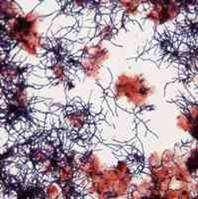

Hydrogen peroxide may be used to correct a serious filamentous bulking situation or, preferably, to prevent one from occurring until adjustments can be made to remove the cause. When applied to the return activated sludge, hydrogen peroxide supplies dissolved oxygen which helps restore the microbial activity necessary for effective operation, while selectively oxidizing the filaments which retard settling. The effective dose of hydrogen peroxide is a function of time and concentration, and varies from plant to plant. To correct a serious bulking problem, immediate results may be obtained by adding 100 - 200 mg/L H2O2 to the biosolids recycle line. Once control of bulking is obtained, the dose may be reduced to 25 - 50 mg/L H2O2 to prevent re-occurrence.

Practical Considerations

Filamentous bulking of municipal activated sludge is not a normal occurrence, and suggests more fundamental problems may be at work (e.g., low dissolved oxygen, high sulfide input, heavy organic loading, nutrient imbalance, improper sludge age, or rapid changes in influent characteristics). Consequently, the use of chemicals such as hydrogen peroxide to control bulking should be pursued in concurrently with more fundamental corrective measures.

Evaluation Process

Evaluation Process

While laboratory modeling of the activated sludge process is possible, it is generally more practical to move directly to a field trial. Before doing so, the project team should confirm the filamentous nature of the biofloc (as opposed to other forms of bulking), and agree upon a common measure of performance (e.g., the SVI - sludge volume index). Once control is obtained, ample time should be allowed for changes in the hydrogen peroxide dose to take effect. With lower doses of hydrogen peroxide (e.g., < 100 mg/L), several days may pass before the effects are evidenced in the biofloc. Finally, related operating data and wastewater parameters should be collected before, during and after the trial to assist in interpreting the results.

Back to top

Get More Information

Contact USP Technologies for more information on our products and services: