Cooling Towers and Process Water System Cleaning Applications Using Hydrogen Peroxide

The unique properties of hydrogen peroxide (H2O2) make it a good technology for keeping cooling loops, process water loops and heat exchangers clean from fouling that can occur due to various contaminants in the water. Hydrogen peroxide works well in removing organic fouling on surfaces through mechanical means and in specific applications through biocidal mechanisms.

Hydrogen peroxide can be used in a shock treatment mode where it is fed based on a timer set-up. It can also be used occasionally at higher concentrations for maintenance cleaning purposes of fouled heat exchangers, cooling water loops and process water loops. Performing an occasional shock cleaning of a heat exchanger with hydrogen peroxide can remove buildup from surfaces and can result in improved heat transfer efficiency. By removing surface fouling, hydrogen peroxide may also improve the efficiency of other biocides such as bleach, bromine and non-oxidizers.

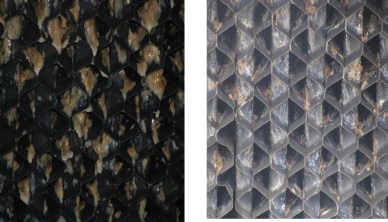

Before and After Cleaning

Download our Case Study for Cooling Tower Cleaning (pdf)

Back to top

Get More Information

Contact USP Technologies for more information on our products and services: